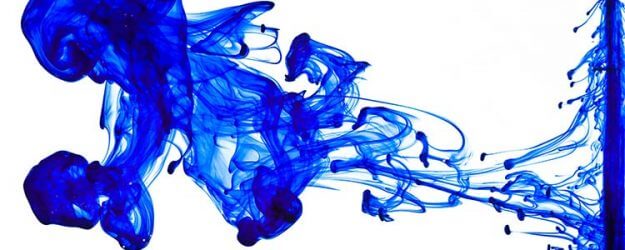

What is Dispersion?

A particle dispersion is a homogeneous distribution of materials in a liquid phase. High-quality dispersions typically possess high stability with a long shelf-life, resist sedimentation and exhibit the customer’s targeted rheology. AVEKA creates micro- and nano-particle dispersions for a wide variety of industries by utilizing bead milling, high-pressure homogenization and high-shear mixing methods.

Dispersion processing is a three-part process:

- Wetting of particle surfaces in a liquid medium

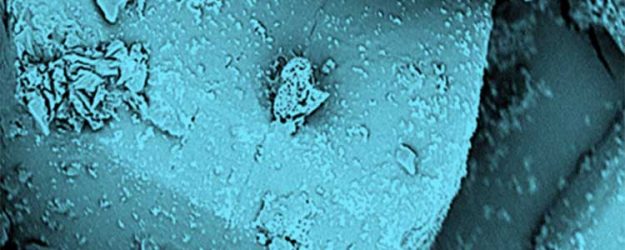

- Mechanical size reduction of solid particles that are either flocculated, agglomerated, aggregated or crystalline

- Stabilizing the newly reduced particles in the dispersion by preventing re-agglomeration using surfactants and/or dispersants

The stability of a dispersion greatly depends on the particle or droplet size as well as the formulation chemistry. Control and manipulation of inter-particle forces is critical to successful dispersion processing. AVEKA‘s team has the expertise to determine the best equipment and processing parameters, as well as assist with the optimization of the dispersion formula. AVEKA‘s in-house Characterization Lab has the analytical capabilities to measure and verify key dispersion properties: particle size, solids content, color strength, opacity, stability and rheology. Once methods and formulations are determined, AVEKA also has scale-up and production capabilities to meet a variety of manufacturing requirements.

AVEKA has the expertise to create high-quality particle dispersions for you!