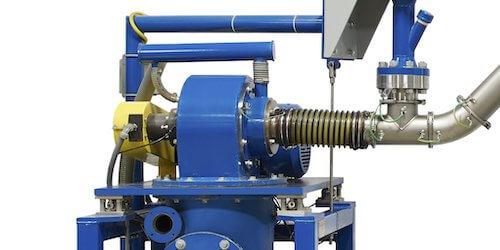

AVEKA CCE designs, builds, and sells fluidized bed jet mills custom to your milling needs. AVEKA CCE’s Fluidized Bed Jet Mills are able to achieve fine particle sizes at high throughput with narrow particle size distribution. Sizes as fine as 1 micron are possible with some materials. The mills are also effective at milling very abrasive materials with minimal wear because the system relies on particle-on-particle impact and is built with wear-resistant surfaces and components. The AVEKA CCE mills are uniquely valuable in terms of efficiency when compared to 1) other dry milling methods by which to achieve ultra-fine particle sizes, or 2) wet grinding methods which require a costly drying step thereafter.

AVEKA CCE Technologies also offers a lab-scale jet mill. The Model 20 Opposed-Jet Lab Pulverizer is designed to be used in closed circuit with the Model 100 Classifier (link to Air Classification) for the production of dry powders, in lab size quantities, at rates up to 4.5 kg/hr. The Model 20 has similar capability in terms of particle size to the Fluidized Bed Jet Mills. This closed circuit combines the particle-to-particle impact of opposed jet fluid energy milling with high efficiency classification, resulting in the production of steep distributions with close top size control. This combination allows the user to expand the versatility of the lab classifier in the production of small quantity, narrow distribution products with a minimum of equipment adjustment.

AVEKA CCE Technologies will work closely with you to understand your need and which model(s) bet fits your application. AVEKA CCE engineers will work with you to customize the system to fit well within your process and bring value to your project, ensuring that your needs are met with the precision equipment that AVEKA CCE offers. Call AVEKA today to custom build your new Fluidized Bed Jet Mill.