Wet Blending for Environmental Use

Wet Blending for Environmental Use

The Challenge: AVEKA was approached by a customer to help formulate and produce a liquid slurry with various ingredients for use an environmental application. The process involved the incorporation of dry...

Water Purification: How AVEKA is Spray Drying the Future of Powder Processing

Water Purification: How AVEKA is Spray Drying the Future of Powder Processing

There’s no denying that liquids are essential to our everyday lives. We use liquids as fuel, lubricants, solvents, coolants, and much more. Water—the most universal liquid—makes up nearly 60% of...

Washing and Decanting to Increase Protein Content of a Plant-Based Flour

Washing and Decanting to Increase Protein Content of a Plant-Based Flour

The Challenge: A customer was interested in increasing the protein content of a plant-based flour. The processing steps are well-known in the industry but require a large and specific suite...

Vibratory Screening of a High-Value Material

Vibratory Screening of a High-Value Material

The taste of cocoa powder and the solidity of cement are just a couple of examples of how particle size can have a significant impact on a product’s chemical and...

Vibratory Screening of a Fragile Powder

Vibratory Screening of a Fragile Powder

The Challenge: A fragile, low-density, organic powder required classification into three narrow particle size ranges: 250-180 µm, 180-150 µm, and 150-125 µm. Unfortunately, the customer's previous attempts at vibratory screening...

Ultrasonic Vibratory Screening for Fine Powders

Ultrasonic Vibratory Screening for Fine Powders

The Challenge: AVEKA was approached by a customer to create a more reliable and effective way to classify their fine, low-density powder. At their current toller, the fine material was blinding...

Tray Drying of a Wet Cake

Tray Drying of a Wet Cake

The Challenge: A customer approached AVEKA with a wet cake and requested it be dried and annealed to achieve a certain material hardness. The previous toller had inconsistent hardening results, which compromised...

The Advantages of Agglomerated Powders

The Advantages of Agglomerated Powders

Fluid bed agglomeration processing Why Fluid bed Agglomeration? In a time where everybody seems to look for ultra-fine particles, agglomerated, larger particles might appear undesirable. But there are significant advantages...

Tablet Coating to Coat Material Used in Pet Care

Tablet Coating to Coat Material Used in Pet Care

The Challenge:The customer was in full production when a devastating hurricane destroyed their current manufacturing facility and the main crop that was required for the product, sugar. The customer quickly...

Spray Drying Highly-Engineered Particles

Spray Drying Highly-Engineered Particles

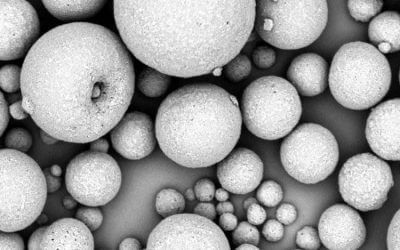

The Challenge: The customer was looking for a way to create ceramic particles for a specialty application. Particle morphology was important: particles could not be hollow, broken or irregularly shaped....

Spray Drying Cosmetic Ingredients

Spray Drying Cosmetic Ingredients

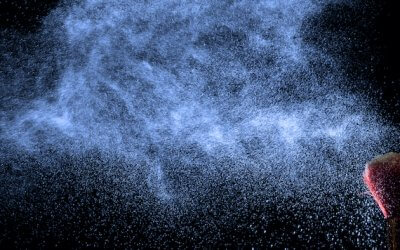

At AVEKA Group, we’ve processed a wide range of personal & beauty care products over the years. By utilizing and executing a variety of methods—such as fluid bed drying, dry...

Spray Drying and Processing of a Nutraceutical

Spray Drying and Processing of a Nutraceutical

The Challenge: AVEKA was approached by a nutraceutical company to produce their powdered product, which is used as an herbal supplement. They were transitioning away from their current toll manufacturer, who...

Sodium Alginate for a Live Organism Delivery System

Sodium Alginate for a Live Organism Delivery System

The Challenge: The customer came to AVEKA with a need to deliver a live organism to the intestines, as well as increase production rates for the viable cells. Sodium...

Sensitive Particles? Lay Your Fears to Rest With Fluid Bed Drying.

Sensitive Particles? Lay Your Fears to Rest With Fluid Bed Drying.

The vast majority of people today have likely never heard of fluid bed drying. Yet in the world of powder processing and toll manufacturing, it is an essential processing platform...

Scaling Up a Food Grade Product Using Fluid Bed Drying

Scaling Up a Food Grade Product Using Fluid Bed Drying

Quite often we have customers come to us with an idea for a material or product that – they fully admit – they are not sure how to create. Fortunately...

Repackaging a Food-Grade Material

Repackaging a Food-Grade Material

You probably don’t think much about it, but there is a lot more that goes into packaging than you may realize. A package is responsible for containing, protecting, preserving, transporting,...

Particle Coating for an Automotive Abrasive

Particle Coating for an Automotive Abrasive

Particles are a lot like people; They’re complex, plentiful, and highly vulnerable to the elements in their natural form. Whereas humans can put on a coat in inclement weather, so...

Our New Personal & Beauty Care Production Suite

Our New Personal & Beauty Care Production Suite

Our AVEKA Inc. facility in Woodbury, Minnesota has recently completed a brand-new production suite dedicated to the unique needs of our customers in the Personal Care & Beauty industry. Now...

Need Particle Processing R&D? These Are Your Top 3 Options

Need Particle Processing R&D? These Are Your Top 3 Options

Particles and powders are present all around us. They exist in almost every industry, including cosmetics, food and beverages, microelectronics, aerospace and automotive, and industrial materials to name a few....

Nano-Dispersion for a Medical Application

Nano-Dispersion for a Medical Application

The Challenge: AVEKA was approached by a customer to help with the scale-up of their pigmented nano-dispersion for a medical application. The customer's existing formulation had a very low solids concentration,...

Melt Spraying to Create Spherical Wax Particles

Melt Spraying to Create Spherical Wax Particles

Used for far more than just candles and crayons, wax is one of those remarkable yet commonplace materials that never ceases to amaze with its wide range of practical applications....

MAIC to Surface Modify Particles & Increase Flowability

MAIC to Surface Modify Particles & Increase Flowability

The Challenge: AVEKA's technical team was asked to change the flow properties of a particle. Fumed silica is typically added to a material in order to make the material flow...

Layer by Layer: How Jet Milling and Air Classification Produce the Optimal Building Blocks for Additive Manufacturing

Layer by Layer: How Jet Milling and Air Classification Produce the Optimal Building Blocks for Additive Manufacturing

In the early 2010s, the process of additive manufacturing was beginning to really take off. While not a new technology by any means (the concept had already been around for decades), the seemingly...

Jet Milling Materials for Battery & Microelectronic Applications

Jet Milling Materials for Battery & Microelectronic Applications

From microchips to lithium-ion batteries and everything in between, there is certainly no shortage of microelectronics production going on in the world today. Whatever your battery or microelectronic production needs,...

Jet Milling for Contamination-Free, Narrow Particle Size Distribution of an Abrasive

Jet Milling for Contamination-Free, Narrow Particle Size Distribution of an Abrasive

The Challenge: The customer approached AVEKA requesting a contamination-free milling process for an abrasive product requiring tight particle size control and a narrow particle size distribution. The customer previously had used ball...

Jet Milling Engineered Thermoplastics for an Aerospace Application

Jet Milling Engineered Thermoplastics for an Aerospace Application

At AVEKA, we’ve helped many different clients in aerospace and other highly specialized industries over the years. From proprietary polymers and resins to chemical agents and reactants, we’ve worked with...

Hammer Milling a Polymer Pellet

Hammer Milling a Polymer Pellet

Back in the Stone Age, when a Neanderthal man wanted something crushed down, he would simply strike it repeatedly with a hard rock until it was the desired size. Fast...

Hammer Milling a Food-Grade Material

Hammer Milling a Food-Grade Material

Typically, when you think of a hammer being used in the food industry, you’re most likely imagining a meat tenderizer or similar kitchen gadget. But what many people don’t realize,...

Fluid Bed Drying to Create a Dry Powder

Fluid Bed Drying to Create a Dry Powder

The Challenge: The customer needed to lower the soluble salt level of ground shells to qualify the material as a filler in subsequent processing. For ease of handling up stream,...

Dry Water Encapsulation for Personal Care

Dry Water Encapsulation for Personal Care

The Challenge AVEKA was approached by a beauty care company to create a dry water personal care product. The customer had an aqueous liquid formulation to be encapsulated, creating a free-flowing...

Dry Blending a Kosher Food Product

Dry Blending a Kosher Food Product

A customer recently approached us with a new formula for a food-grade product that involved dry blending the ingredients with an additive. They requested a volume of 80 metric tons...

Developing an Environmentally Friendly Alternative to Plastic Microbeads

Developing an Environmentally Friendly Alternative to Plastic Microbeads

You wouldn’t knowingly rinse a plastic container down the drain, would you? Of course not! Unfortunately, you may be surprised to hear that according to a report by the United...

Characterization of Flavor Powders

Characterization of Flavor Powders

The Challenge: The customer had several seasoning powders that behaved differently in a snack food coating application. These seasonings were not attaching to the snack food surfaces as desired, resulting...

Bead milling a proprietary water-based coating

Bead milling a proprietary water-based coating

Whether your area of expertise is in printing, electronics, cosmetics, or agrochemistry, there is likely a need for micro-fine particle dispersions in any new product development. AVEKA has been processing particle dispersions and specialty coatings for...

Ball Milling for Size Reduction of High Purity Materials

Ball Milling for Size Reduction of High Purity Materials

The Challenge: The customer was looking for a way to reduce the particle size of their specialty value-added ceramic pigment. While size reduction is a common request, in this case...

Alginate Beads for Eye-Catching Abrasives

Alginate Beads for Eye-Catching Abrasives

The Challenge The customer was looking for a visually appealing large bead to be an abrasive in a consumer home care product. The beads needed to be aesthetically pleasing, requiring...

Air Classification with a Narrow PSD and Impacts on Yield

Air Classification with a Narrow PSD and Impacts on Yield

The Challenge: The customer was looking for a way to classify their glass powder waste to be used in a new application. To fit the new application, the glass needed...

A Complete Guide to Purchasing an Air Classifier

A Complete Guide to Purchasing an Air Classifier

Is your business considering purchasing precision air classification equipment for fine particle separation at a high throughput? Whether you’ve been toll manufacturing your materials for years or have a new...

A Complete Guide to Purchasing a Jet Mill

A Complete Guide to Purchasing a Jet Mill

Is your business considering purchasing precision jet milling equipment for fine particle size reduction and increased throughput? Whether you’ve been toll manufacturing your materials for years or have a new...

No Results found, please adjust your filters