by Kerstin Iverson, Sr. Business Development Manager at AVEKA Woodbury

Sustainability and environmental impact are moving increasingly into focus for Contract Manufacturers pushed by their customers growing demand for eco-friendly and socially responsible practices. How does AVEKA manage these new challenges?

AVEKA has implemented an Environmental Management System (EMS) as a systematic approach to handle environmental issues, ensure compliance with environmental regulations, and promote sustainable work practices. The primary goal is to reduce AVEKA’s environmental footprint.

Here are several AVEKA initiatives for better environmental management:

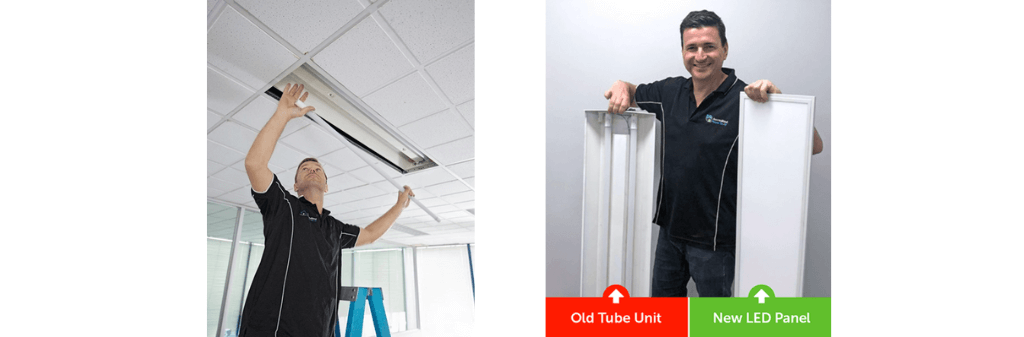

1. Implementing Energy-Efficient Practices:

Starting with exchanging old fluorescent light bulbs with new LED lighting, AVEKA did not just brighten their workspaces, but reduced their electrical utilities bill significantly. In addition, a thorough audit with the Utilities provider delivered additional savings potential by modifying equipment motors and electric charging stations. Long term projects include the investigation into sustainable energy resources such as solar energy and energy efficient cooling options to reduce carbon emission and operational costs.

2. Waste Reduction and Recycling:

Several years ago, AVEKA established a waste recycling program throughout the plant and offices. Newly launched initiatives focus on the overall reduction of hazardous waste and the reduction of paper usage.

3. Water Conservation:

AVEKA Nutra Processing in Waukon, Iowa has installed a new wastewater treatment station. This system helps neutralize wastewater which significantly reduces the contaminants released to the city’s water system and shows AVEKA’s commitment to be a better steward of their communities. New initiatives include the installation of circular cooling systems for production equipment which will help reduce the amount of fresh water used for operations.

4. Reducing Emissions and Pollution:

As a Contract Manufacturer, AVEKA pays special attention to emissions created during processing. Emissions are closely monitored and controlled to avoid the release of pollutants. AVEKA is very careful in selecting the right projects to avoid emitting excessive gases or substances from their operations. Where odors cannot be avoided, special ventilation systems with air scrubbing devices have been installed to reduce emissions into the environment.

5. Employee Engagement and Continuous Improvement:

As an employee-owned company, AVEKA employees are actively encouraged to present ideas for continuous improvements and sustainability initiatives. Engaged employees are crucial for AVEKA’s success. Regular announcements on the company’s information system and through the internal Newsletter keep every employee aware of the company’s environmental goals and progress.

By implementing an Environmental Management System, AVEKA has started a path to improve accountability on its environmental impact and is well on its way to reducing its environmental footprint.